Company Name: HELLA Corporate Center Asia

Project Name: Battery management system

Award Category: Innovation Sustainable Product

Product / Service Introduction

HELLA's battery management system monitors the voltage, temperature and current of lithium-ion batteries and performs a variety of safety-related functions, including those related to high voltage. It is worth mentioning that thanks to the modular, scalable design, it can be integrated into a wide range of relevant power electronics independent of the battery technology used, and on this basis ensures a high degree of flexibility that can be applied to different batteries and models.

The Battery management system (BMS) not only directly manages the charge and discharge of the power battery, but also serves as a link between the battery pack, the vehicle system and the motor. Battery management is one of the key technologies in electric vehicles, which plays a role in safety monitoring and effective management of battery packs, improving battery efficiency, and managing the entire life cycle of batteries. It can better promote the development of battery recycling economy.

Explanation of Circular Economy Practice

HELLA’s battery management system contributes to energy reduction, emission reduction, reducing energy loss and improving energy efficiency of electric vehicles. In addition, it strengthens the range and improves the safety of vehicles. With these solutions, users can travel further on shorter charges, while enjoying a more comfortable electric driving experience and a more sustainable future.

BMS can better promote the development of battery recycling economy. Specifically, the number of electric vehicles driving on the road has increased, which means that the global battery production needs to further increase every year, which has increased by more than three times. This means that BMS can better control the entire battery life cycle and promote battery cycling.

For example:

- During battery assembly and consolidation, including before its use, BMS can be used to better investigate the performance and condition of the battery.

- During the use of batteries, we can monitor and trace their health status. After the cascade utilization is completed, we can also better understand the usage status and data of batteries, which will benefit the entire ecosystem.

Overview of Product/Service Lifecycle

Product Design:

- Miniaturized and lightweight design

- Flexible concept design for EVs and HEVs, It can also be recycled and reused

- The mature software algorithm of SOH has a positive contribution to the subsequent recycling and utilization of battery cells

Production:

- Reduce raw material consumption and reduce cost

- Innovate production processes, improve production efficiency, and reduce greenhouse gas and waste emissions

- Product life cycle assessment system, product carbon footprint report

Useage:

- Monitor and trace the health status of batteries

- Control the entire battery life cycle to promote battery cycling, during battery assembly and consolidation

Recycling and Recovery:

- After the cascade utilization is completed, we can also better understand the battery usage and data, which will be beneficial for the entire ecosystem

- The inconsistency between battery modules will significantly worsen after restructuring, which requires the active balancing function of BMS to solve

More Product / Service Highlights

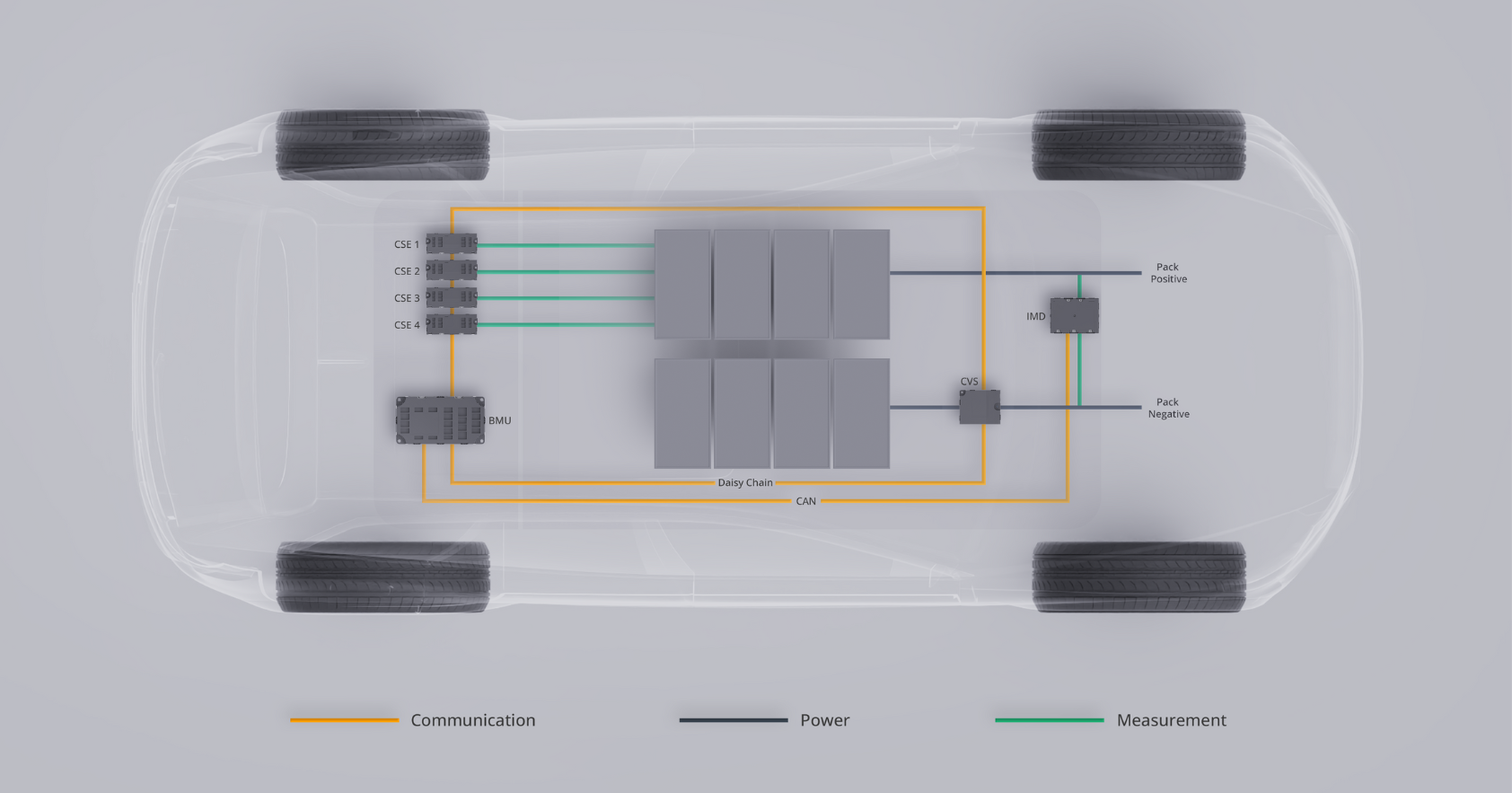

HELLA's high-voltage battery management system solutions are equipped with industry-leading core components, including high-voltage battery management system (BMS), shunt-based high-voltage current sensor (HVCS), and insulation monitoring device (IMD) based on active/passive measurement technology. Among them, the high-voltage battery management system monitors the voltage, temperature and current of lithium-ion batteries and performs a variety of safety-related functions, including those related to high voltage. It can be integrated into a wide range of relevant power electronics independent of the battery technology used. Thanks to its modular and scalable design, it can be applied to different batteries and vehicles because of high flexibility for design.

HVCS products are innovatively developed based on the intelligent battery sensor (IBS, whose main purpose is to detect the lead-acid battery status of conventional 12V start-stop systems), a star product that has sold more than 10 million sets. Proven products and technology ensure the safe use of lithium batteries.

IMD is designed to support not only the traditional passive insulation detection that relies on high-voltage signals, but also active detection methods that support signal injection. At the same time, as one of the developers for ISO 26262 functional safety standard, we have an in-depth understanding of functional safety and the ability to design high quality and reliable BMS which is safety related product.