Company Name: Klüber Lubrication (Shanghai) Co., LTD.

Award Category: ESG Performance

Company Size: Medium-sized Enterprise Group

Environment

Climate Change:

Klüber China is committed to achieving the dual carbon goals and Kluber’s carbon neutral goals. Our goal is to achieve climate neutrality by 2045 and 90% green electricity by 2030. Based on this, we have developed a carbon neutrality roadmap and implementation map. Specific measures include reducing direct carbon dioxide emissions by reducing the use of high-GWP materials through electrification, reducing scope 2 emissions by purchasing green electricity and signing PPAs, and finally offsetting the remaining carbon dioxide through carbon sequestration projects. (Due to the long construction time, the design load-bearing of the roof is not enough to support the photovoltaic panels, so photovoltaics are not included in the carbon reduction measures.)

At present, Kluber China's direct carbon emissions are 475t and indirect carbon emissions are 1656t, which are respectively 14% and 1.3% lower than in 2019 (base year). Scope 3 has made a preliminary estimate this year, and the next step is to prepare for third-party verification and formulate scope 3 carbon reduction measures.

In this year, we plan to purchase green electricity certificates for 30-50% of the total electricity in October to meet our 100% green electricity goal in 2025.

We plan to further reduce the use of high-GWP solvents, increase investment in bio-based lubricants and lubricants for waste oil recovery and product development.

Kluber China has passed the carbon inventory of ISO14064 through SGS. In addition, we mobilize through a series of activities to promote the concept of sustainable development and low-carbon environmental protection.

Natural Resources and Energy:

Klüber China conducted an energy audit last year, and is now making rectifications based on the audit results. In the future, it will purchase high-efficiency motors and replace them with oil-free screw compressors.

Current countermeasures against resource consumption:

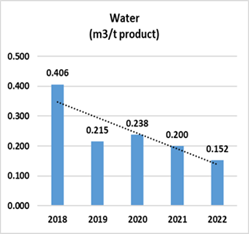

When switching production products, instead of washing directly with fresh water, it is improved to first wash with the same batch of base oil, then wash with recycled base oil, and finally rinse with fresh water, which greatly reduces the amount of fresh water . In 2022, save fresh water consumption and reduce hazardous waste by about 34 tons each.

The company's warehouse and production workshop originally used metal halide lamps, which were replaced by LED lamps at the end of 2014. Total investment: 190,000 yuan. It is expected to save 80160 kWh/year of electric energy.

High-viscosity raw materials will remain in the barrel after feeding, causing waste of materials and increase of hazardous waste. Therefore, the company will invert the used high-viscosity material barrel for 3~5 days to collect the remaining material. In 2021, a total of 10.5 tons of high-viscosity raw materials will be collected.

The external wall and roof of the old administrative building of the company are equipped with external thermal insulation layers. The external wall is made of 100 mm glass wool and covered with hollow granite slabs; the roof is made of 150 mm thick XPS foam and Sarnafil roof plastic film; all external windows The glass is made of heat-insulating aluminum alloy, and there is a Low-E coating inside the hollow argon-filled double-glazed glass. Sun visors are installed on the outer windows to prevent direct sunlight from irradiating the building, and the outer doors of the building are double doors, which play the role of heat preservation and heat insulation, thereby achieving a good energy-saving effect.

The interior and exterior walls of the new administrative building newly completed by the company in 2014 are made of 100mm thick aerated concrete blocks. The outer wall is insulated, using stone + 160 thick rock wool (180kg/m3) + 200 thick concrete hollow blocks, so that the heat transfer coefficient of the stone curtain wall is not greater than 0.2 W/(m²·K); the outer window frame is made of Aluminum alloy window frame, the glass is made of 10(Low-E)+12A+10+12A+10 three-layer double insulating glass, and the heat transfer coefficient is 0.8W/(m²·K). The roof is insulated with 120 thick rock wool (80kg/m3) insulation boards. In addition, the building ventilation system is equipped with a liquid circulation heat recovery section in the exhaust duct to recover the waste heat of the exhaust air, thereby realizing heat energy recovery. The energy-saving design of the building enables the company to achieve pre-management in terms of energy conservation.

Prevention of Pollution :

Establish an EHS system, establish a hazardous waste management system, hazardous waste management chart, post responsibility system and safety operating procedures, and clarify the content of the system and the information of the person in charge.

The facilities and places for collecting, storing, transporting, utilizing, and disposing of hazardous wastes, as well as the containers and packages of hazardous wastes must be provided with identification signs of hazardous wastes.

Formulate a hazardous waste management plan, including waste storage, utilization, and disposal measures, and report to the local environmental protection county bureau for filing in a timely manner. If there is any major change in the content, it should be reported in time.

Carry out source separation, such as hazardous waste, general waste, gaseous waste, etc. for separate storage

Formulate accident prevention measures and emergency plans, and file with the local county ecological environment branch. According to the requirements of the plan, write an emergency drill plan, organize emergency drills, and use photos or videos to record the drill process

Other Actions Taken for Environmental Protection:

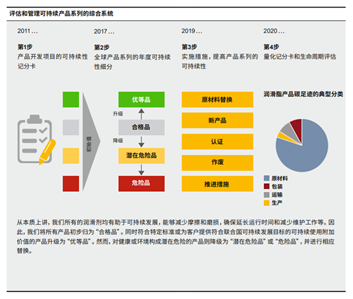

We have deployed a line of biodegradable products, mainly for applications where leakage of lubricants into the environment is difficult to avoid (such as the marine sector). These products are certified by Ecolabel, OSPAR or EAL. Some of our products have been proven to reduce lubricant consumption, generate less waste and minimize impact on the biosphere. We call these products "superior products" and evaluate such products through the SPPS system, and then promote them.

Our aim is to understand our impact on the biodiversity and surrounding environment where we operate in order to develop measures to minimize negative impacts and make a positive difference. Each of our factories participates in various local sustainability projects every year. Provide opportunities for our employees to actively participate and make a small contribution to learning more about the relevance of biodiversity.

Social

HR Development and Engagement:

Klüber Lubrication has adopted an HSE management system, which covers specific preventive measures for each process and is continuously improved by the global HSE team. We have guidelines for quality, environmental protection, workplace safety, health and diversity. The guidelines primarily state that we must always comply with laws, regulations, and internal and external system standards, and create a safe and healthy workplace. It also states that our aim is to minimize the risk to our customers and the hazards to our employees. We have taken the effect of the "5S approach" on ensuring workplace safety and through this approach reduce health and injury risks due to confined spaces.

Employee Benefits:

Our training concept is designed to support Klüber Lubrication's vision and strategy as effectively as possible and thus drive the company forward in a timely and targeted manner. Through continuous training, new employees and old employees can effectively master the necessary new skills and apply them in practice as soon as possible. We require employees to pay attention to the needs of customers. In line with the principle of "Learning never ends", we encourage employees to continue to participate in advanced training and development programs. At the same time, we continuously adjust the training program according to the needs, create as much added value as possible and make the program more attractive. To evaluate the results of the training we provide, we measure student satisfaction, quality of training and effectiveness of training. We also calculated the "hours of training per person" and set a target of 5 days per year. What we do We use the learning management system of our parent company, Freudenberg, to conduct global, interdisciplinary and cross-functional training. At the same time, we drew on the training content provided by Freudenberg. The basic training content includes new employee induction training, technical basic training and product training. We further expand the scope of training, offering mandatory training courses, such as IT security, data protection and GDPR or export control. Other training topics include building a diverse and inclusive work culture, preventing corruption and sustainable development, among others. In addition, we provide a range of necessary language and management skills as well as other soft skills training. We encourage local training teams to share information and exchange relevant experiences with each other. By 2022, 100% of Klüber Lubrication employees will have participated in training activities. The average training time per person was 5.43 days, one day more than last year (4.05 days), and higher than the goal we set (5 days). This growth is mainly due to the digital training method. The duration is getting shorter and shorter, but the learning mode with more and more frequent classes is still the mainstream learning method in 2022. In 2022, the completion rate of IT security training will exceed 86.3%.

Diversity,Equity and Inclusion :

To meet our own requirements, we implemented the following measures in 2022:

Quarterly progress meetings are held by our Global Diversity Council as well as our Regional Diversity Councils in Europe, North America, Asia Pacific, China and South America/Australia

Roll out Freudenberg's diversity and inclusion curriculum to all employees

Pay attention to the proportion of mentor selection for female candidates

A commitment to screen and hire (if appropriate) at least one female candidate for each position and we will continue to follow up on this requirement

Invest in employment companies that provide services for people with disabilities

Product Liability:

Monitoring and management of product safety and quality:

Our aim is to minimize the environmental impact of our products, facilities and activities, and to actively contribute to the protection of biodiversity and ecosystems. To this end, we have adopted a Life Cycle Assessment (LCA) approach and are looking for ways to identify a product's carbon footprint and include it in our quantitative score (step 4). This comprehensive system provides the basis for a comprehensive analysis and presentation of our impact on ecosystems and provides solutions for reducing our carbon footprint. Our aim is to minimize long-term impact on the environment and protect ecosystems and biodiversity.

How to improve customer service:

Online monitoring service

With LuCA (Lubrication Condition Analysis), we have developed a solution to determine the best time to change lubricants. This solution prevents increased wear and avoids unnecessary lubricant consumption. Klüber Lubrication Laboratories' lubricant and grease analysis services provide information on lubricant composition, impurities, wear, oxidation and aging. LuCA was officially launched in October 2022 and quickly won the favor of customers. It follows the principles of risk management and Total Productive Maintenance (TPM), laying the foundation for efficient maintenance processes and effective predictive maintenance.

Remote expert service

Through Remote Expert Service, our global network of tribologists, service engineers and other technical specialists provides immediate on-site support to customers. This new innovative support service reduces travel-related CO2 emissions by using visual inspection technology to access factories remotely, eliminating the need to physically travel to customer sites. Not only that, but customers get top-notch professional support without delays due to travel time. This service not only optimizes processes but also reduces potential downtime, thereby contributing to more efficient and sustainable use of resources.

Comprehensive production management service

Our customized digital solutions not only support users to implement TPM, but also help them achieve sustainable development goals. We assign a QR code to each lubrication point and record it in the Klüber EfficiencyManager1 software to provide an instant overview of the status of the components. In this way, customers are able to obtain precise information on wear points, thereby reducing the risk of incorrect lubrication and under/over lubrication. We also use additional measuring equipment to measure electricity consumption and identify potential energy savings. Our new digital initiatives help customers reduce costs and increase their sustainability.

How to protect customer rights and interests:

We are all able to provide you with the right product for your specific application. Using a matched lubricant can greatly extend lubricant change intervals, reducing annual waste disposal. To clearly demonstrate energy savings to our customers, we provide proof of accurate measurements and compliance with international standards. As a result, customers can make investment decisions on a solid basis and use improvement measures for ISO 50001 certification.

In 2022, the Klüber Energy service recorded energy savings of 438 gigawatts, equivalent to 67,000 tons of CO2. This is more than the annual maximum emissions from our factories (49,000 tonnes in 2019) and more than eight times our global energy consumption (50 gigawatts). Through this service, Klüber China has helped customers save a total of 59,960MWh of electricity, equivalent to 32,100 tons of CO2.

Supply Chain:

Supplier Selection & Evaluation Mechanism:

We have developed our own comprehensive standards for sustainable procurement, which form the basis for our cooperation with suppliers. So since 2015, we have been implementing a Supplier Code in line with the principles of the UN Global Compact. Both existing and new suppliers must comply with the Supplier Code. During the admission process of new suppliers, we will rate and evaluate the qualifications of suppliers, such as whether the raw materials of the products meet the standards and whether they have relevant qualifications. In order to identify potential negative environmental and human rights impacts of factors in the supply chain, we use the Eco-Vadis platform, which will be launched in 2022, to carry out related work. With EcoVadis IQ we are able to analyze supply chain risks and further evaluate suppliers with EcoVadis ratings. If necessary, we will jointly take remedial and corrective action with the supplier. In this way, we ensure that CSR issues in the supply chain are publicly visible.

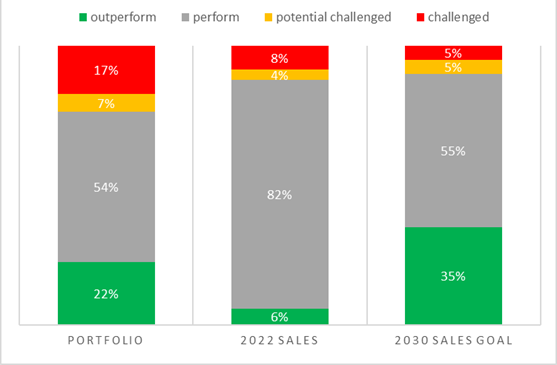

ESG strategy:

Suppliers must agree to abide by our code of conduct, and suppliers themselves must develop a code of conduct that meets our expectations or sign the United Nations Global Compact. We refuse to work with suppliers who do not meet this criterion. All suppliers of raw materials and packaging to Klüber Lubricants shall comply with this condition. In 2022, we established new business relationships with 72 raw material and packaging suppliers. All suppliers are expected to complete the onboarding process in accordance with the above requirements and undergo a risk assessment on EcoVadis IQ's environmental and human rights themes. Since the introduction of EcoVadis, we have sent invitations to 100% of our raw material and packaging suppliers by December 31, 2022, inviting them to join Klüber in their commitment to social sustainability and compliance with our requirements for suppliers expectations.

Community Engagement :

Klüber China employees, as members of the Freudenberg Group, participated in the Haijin Hope Primary School invested by the Freudenberg Group this year. While bringing clothes, brushes and other stationery to local children, they also helped local children learn Chinese, subjects such as mathematics.

Corporate Governance

Governance Organizational and Mechanism:

A good reputation is a major factor in Klüber Lubrication's success. We are part of our parent company, the Freudenberg Group, and live by the Group's values, whose business is based on strict ethical standards. Therefore, we expressly prohibit any illegal or unethical conduct in the conduct of our business. A professional compliance management system helps us achieve this goal. It can be said that compliance is an important part of our corporate strategy. We build an open culture at all levels to ensure that the compliance culture is implemented at all levels of the enterprise. Klüber Lubrication adheres to the principles of the Freudenberg Code of Conduct and has established a set of compliance principles. Furthermore, we comply with the guidelines issued by our parent company, in particular the Freudenberg Guiding Principles, Freudenberg business principles, Antitrust Guideline, Anti-Bribery and Anti-Corruption Guidelines (Anti-Bribery and Anti-Corruption Guideline) and Standard Internal Control Catalog (Catalogue of Standard Internal Controls).

Innovation Sustainability:

Innovation is one of the secrets of Klüber's success as a leader in the lubricant industry. Our commitment to innovation is reflected in all aspects: production, products and packaging

Production:

Klüber used a solvent with high GWP (Global Warming Potential) in the production process. The use of several tons of solvent brought more than 300,000 tons of carbon dioxide equivalent emissions to the environment. After discovering this problem, the Kluber China team set up a special research and development project team to find a substitute for the cleaner. After extensive experiments and production tests, the project team finally found a solvent that is more environmentally friendly and uses less. After the proposal was submitted to the Kluber headquarters, it was greatly appreciated, and the solvent was continuously replaced in the past two years. Thanks to this solvent replacement, Klüber's CO2 emissions in 2021 will be 49% lower than in 2019.

Product:

Through years of research and development and technical research, Klüber has provided a comprehensive green lubrication solution for wind turbines, covering all friction points of the wind turbine, making up for the shortcomings of lubrication, and ensuring the efficient and stable operation of the wind turbine. It not only covers the daily operation of the wind turbine, but also aims at the maintenance of core components, and innovatively invented the non-stop bearing cleaning technology, which prolongs the life of the bearing in the "online cleaning, green continuous" and improves the conversion efficiency of wind energy. Further development provides a green solution. As of the end of 2021, Klüber's comprehensive fan green lubrication technology has a market share of about 25% in the wind power industry, assisting China's wind power industry to complete power generation of about 163.9 billion kWh in 2021.

Package:

Klüber China's customers consume tens of thousands of oil barrels of a specific type every year. A large number of hazardous waste oil drums cannot be disposed of in time, so the Kluber team has developed sustainable packaging for oil drums. In the new packaging, the oil drum is no longer hazardous waste, and the lining structure is the only hazardous waste, and its weight is only 0.5kg, which is 97% lower than the weight of the previous hazardous waste. The use of new packaging not only greatly reduces the customer's disposal costs, but also allows the customer to have more space to store hazardous waste. In addition, the new sustainable packaging has solved the problem of residual lubricant in oil barrels. After using the new packaging, each oil barrel can save 1L of lubricant, and the amount of lubricant saved every year is equivalent to reducing hundreds of tons of CO2 emissions. In general, customers can reduce the cost of several million RMB every year by using Klüber's new packaging.