Company Name:Ateliers Phi

Project Name: SHINE Dry Eco Toilet

Award Category: Innovation Sustainable Product

Product / Service Introduction

The solutions we have so far developed are 100% 0 carbon and 0 water products which work in a closed-loop system:

SHINE dry eco toilet® is a 100% 0 drop of water toilet. Designed in a closed loop solution: it turns the waste into resources through an accelerated composting procedure and becomes organic fertilizer at the end.

We offer this disruptive sustainable technically 1st of the world solution in 3 formats:

- The portable toilet for catastrophes, festivals, construction site etc.

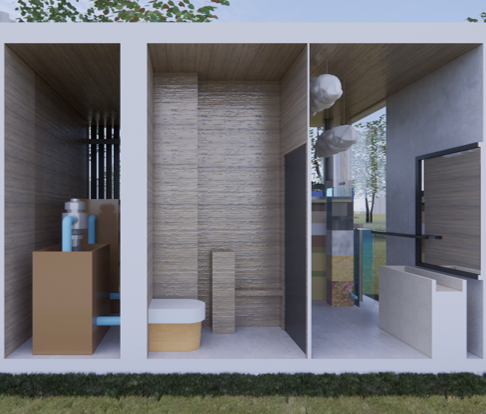

- Indoor fully dry eco toilet with or without vacuum pump depending on built-in situation

- 100% off the grid standing alone public toilet building without necessity to be linked to any grid for water / plumbing, sewage or electricity.

SHINE® water recycling unit fully recycles grey water from handwashing, showering and cleaning water naturally. It can as well be linked to a rainwater collection. Through 2 circuits through natural layers of gravel and sand, the grey water is 100% recycled in the natural way and turned into drinking quality water.

The company develops, sells and rents these systems to target the UNSDGs 6, 1, 11, 13 and 16.

Explanation of Circular Economy Practice

Every day, a shocking amount of precious sweet water, equivalent to at least 300 billion liters, is wasted globally. This water, which could be used for drinking and other essential purposes, is being needlessly flushed down the drain through traditional flushing toilets. This alarming reality compelled me to take action and find a sustainable solution to tackle this issue.

In response to this pressing challenge, we embarked on a mission to develop indoor dry sanitarions. This solutions is designed to operate without the need for water, thus eliminating the wastage of this valuable resource. Instead of using water for flushing, indoor dry toilets rely on a unique system designed to operate without water, utilizing a unique system that incorporates organic materials. This innovative approach not only eliminates the need for water but also transforms waste into a valuable resource – organic fertilizer.

It is definitely works in a closed-loop and adhere to the circular economy.

- The toilet usage is helping to save water.

- The bag production uses waste bamboo material to produce the fully compostable bags to add the needed fiber for the composting procedure.

- The humanure brought to the farm is composted to be turned into organic fertilizer.

- The fertilizer brings back the nutrients to the soil to become more fertile again and again bring crops to be harvested.

This is circularity.

Overview

of Product/Service Lifecycle

Product Design:

The indoor dry toilet solution is thoughtfully designed to operate without the need for water, making it a sustainable alternative to traditional flushing toilets. It incorporates a unique system that is clean and efficiently collects the waste. The product design ensures that the decomposition process takes place in an odorless and hygienic manner, promoting a comfortable user experience.

Production:

During the production phase, special attention is given to using eco-friendly materials and practices. The design incorporates organic materials to facilitate the decomposition process effectively. Manufacturers prioritize the use of sustainable resources and ensure that the indoor dry toilets are durable, long-lasting, and environmentally friendly.

Useage:

Indoor dry toilets are incredibly user-friendly, requiring minimal maintenance and offering a simple disposal process. As the system operates without water, users need not worry about water wastage during "flushing". The waste separation mechanism ensures that solid waste can be transported and then transformed into organic fertilizer, offering a closed-loop approach to waste management. This usage pattern aligns with sustainable practices and encourages responsible waste disposal.

Recycling and Recovery:

The indoor dry toilet system showcases a true closed-loop approach to waste recycling. As the solid waste undergoes natural decomposition, it is transformed into nutrient-rich organic fertilizer. This end product can be safely collected and utilized for agricultural purposes, enriching the soil and promoting sustainable agriculture practices. By recycling waste into valuable organic fertilizer, the system reduces the burden on conventional waste management methods and contributes to a more circular economy.