Company Name: UVEX (GUANGZHOU) SAFETY CO., LTD

Project Name: uvex Safety Shoes

Award Category: Innovation Sustainable Product

Product / Service Introduction

In 2022, uvex created the "protecting planet" label that offers maximum transparency and information about our sustainability activities: from resource-saving products and innovative measures in our factories through to social commitment and social projects. Take uvex 1 G2 planet safety shoe as an example.

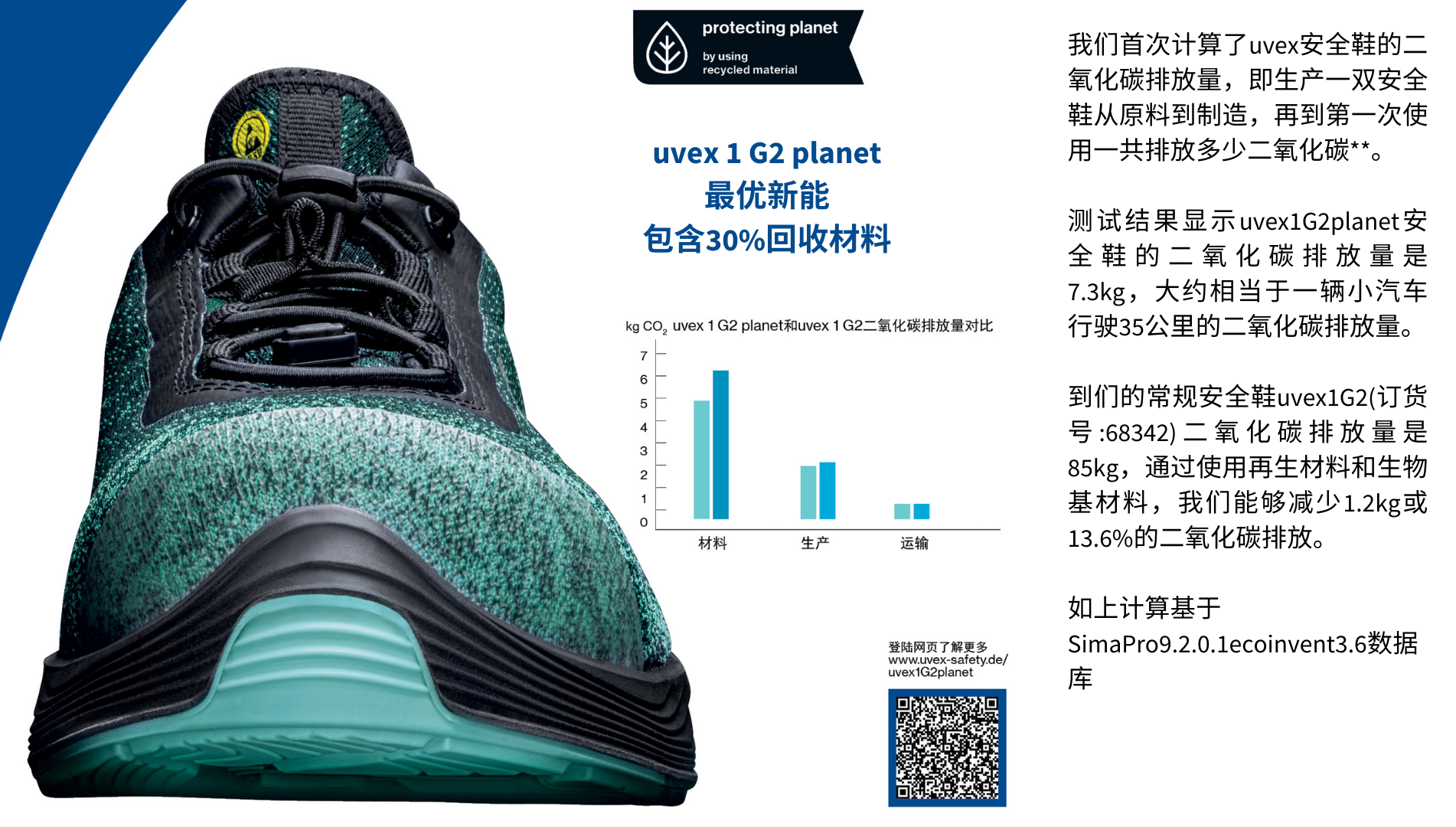

In 2021, the uvex 1 G2 planet was introduced to the market with a recycled content of 25%. It is the first certified safety shoe to have recycled granulate in a direct injected midsole. uvex has became the first company to have succeeded in integrating granulate made of polyurethane surplus from its own production processes into the direct injected midsole of its safety shoes and in launching the fully certified product on the market. This year, it has since become even more sustainable with a recycled content of 30% thanks to the recycled material in the midsole. For the first time, the company also calculated the CO2 footprint of this product in order to identify potential for improvement along the entire value creation chain.

The footwear department at uvex safety has been working to produce greener products since 2011. In addition to the uvex-wide list of banned hazardous substances, which includes more substances than the current REACH regulation, a photovoltaic system has been installed on the roof of the uvex Cagi production site in Ceva, Italy. Since 2013, the department has been implementing projects to reduce waste, which have so far decreased the amount of annual waste by approx. 20%. Since 2017, the Italian production site has been certified to DIN EN ISO 14001 thanks to its environmental management system, and since 2019, the site has been using only green electricity and green gas for production.

Explanation of Circular Economy Practice

"protecting people" is the mission behind all uvex group brands. The aim is to offer people exactly the right protection they need with uvex products. With CO2 emissions rocketing and global warming soaring, the climate crisis is escalating rapidly. Protection in this regard takes on meaning in a wider social, ecological and economic context. protecting people therefore naturally leads to protecting planet. It is only possible to protect people, therefore, by working to preserve and protect the environment.

In little more than a decade, uvex has implemented a considerable number of measures to improve its green credentials and reduced its CO2 footprint by 70 percent (in scope 1 and 2). uvex is working hard to increase energy efficiency in its manufacturing facilities and has set clear goals and defined measures to become carbon-neutral by 2045. High quality standards for products are combined with the development of recycling concepts and the use of bio-based materials. The durability and long service life of uvex products help to reduce waste and conserve resources.

For the first time, we have calculated the CO2 footprint for a uvex safety shoe. This tells us how much CO2 is emitted during the production of a pair. To calculate this, we measured the emissions from the raw materials to the first use*. The result is that the CO2 footprint of the uvex 1 G2 planet is 7.1 kg. This is roughly equivalent to a 35 km car journey. By using recycled and bio-based materials, we were able to reduce the CO2 footprint by 1.2 kg or 13.6% compared to our regular uvex 1 G2.

Calculations based on Sima Pro 9.2.0.1, ecoinvent 3.6 database

Overview of Product/Service Lifecycle

Product Design:

uvex has been blazing a trail for sustainability within the industry. Building on the “protecting planet” range product, the company can also now provide data on the amount of greenhouse gases its products generate, bringing transparency into the whole field of sustainability. uvex calculates the CO2 footprint of products using the measurement method specified in the ISO 14067* standard. For the calculation, various factors such as materials, production processes, transport routes and methods as well as a disposal process are considered. The calculation will also be used as a basis for future design and product development processes.

Production:

The uvex safety footwear plant in Ceva, Italy, was already completely converted to green electricity and green gas a few years ago and has been certified according to the environmental management system ISO 14001 since 2017. In addition, the plant uses renewable energy with a photovoltaic system. uvex places a special focus on waste prevention. For example, some years ago, the shape of the soles were redesigned, which as a result significantly reduced the amount of waste. The cleaning and injection process is also continuously optimized. For some time now, all PU waste is collected and processed into granules ready for reuse. Up to 10 percent recycled PU waste from uvex’s production is used for the TPU outsole of the uvex 1 G2 planet.

Useage:

All uvex shoe boxes are made from 90 percent recycled cardboard. 100 percent recycled tissue paper is used and the instructions for use are also made of 100 percent recycled paper.

Recycling and Recovery:

The upper part of the safety shoe is made from 100 percent recycled polyester made from PET bottles. The penetration resistant midsole is also made from 100 percent recycled materials. 40 percent recycled TPU is used for the TPR scuff cap. The shoe’s distance mesh lining is made from 52 percent recycled polyester and 18 percent bamboo fibres. The replaceable comfortable climatic insole is also made of 100 percent recycled PU foam and polyester. The entire safety shoe is manufactured free from harmful substances according to the restricted substances list created by uvex, which goes beyond REACH. At present, we are already conducting pilot projects with customers to recycle used products, and we will return the recycled products to the factory for re-processing and extract usable materials.

More Product / Service Highlights (Optional)

The uvex i-PUREnrj material used for the midsoles of uvex safety shoes has long been known for its shock-absorption and energy-return features. After several years of development and process optimization, uvex has succeeded in supplementing its i-PUREnrj material with PU granulate from its own production surplus. The process of injecting a coarse-grained compound into a sole mould has existed for many years. However, due to the special processes required to manufacture uvex safety shoes, it is necessary to use horizontal closed molds. As a result, it is not possible to replicate the conventional process exactly. The granulate makes our PU mixture thicker, which blocked the injection nozzles when we first tried to use it. Many adjustments to the channels and production processes had been necessary in order to reach the current market maturity. Thanks to this innovation, we can now reuse and recycle our PU surplus, which has already been reduced in quantity. However, the real highlight is that this midsole has also passed all the necessary tests for safety shoes and combined with our i-PUREnrj technology, features excellent shock-absorption and energy-return properties", says Rebstock. By adding granulate to the midsole, the uvex 1 G2 planet, which was introduced last year with a recycled content of 25% (measured by the weight of the individual parts and in accordance with DIN EN ISO 14021), can now be replaced by the same model but with a recycled of content 30%.