By Nathalie Ieong, Operation Manager at TERAO Asia

Gaspard Lemoine-Scelles – Business Development Manager at TERAO Asia

Sustainability is a growing concern for governments, corporations, and civil society. Leading economies such as China and the European Union have announced ambitious carbon neutrality targets and climate change action plans.

At the corporate level, more and more organizations – large companies and SMEs – have strengthened their corporate social responsibility guidelines by setting up clear improvement goals for sustainability, including carbon reduction & carbon neutrality plans. These objectives are becoming a reality with short-term targets.

This article aims to provide a comprehensive explanation of carbon footprint, how to calculate it, and how to set up an action plan toward reduction & neutrality.

Methodology Introduction

The carbon footprint can be evaluated using the GHG protocol.

What is GHG protocol?

Firstly published in 2001, the GHG Protocol provides guidance on quantifying and reporting a company, project, or product's Greenhouse Gas (GHG) emissions, developed by the World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD).

It covers six greenhouse gases identified in the Kyoto Protocol: carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), and sulfur hexafluoride (SF6). All GHG emissions are converted into equivalent CO2 emissions: kgCO2e.

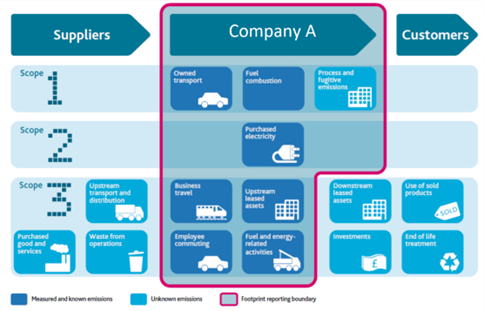

Three different scopes are defined for GHG accounting and reporting purposes:

Scope 1: Direct GHG emissions from the company’s assets (fuel burning, use of company vehicles, processes inside company’s facilities, etc.)

Scope 2: Electricity Indirect GHG emissions for the generation of purchased electricity that is consumed in the company’s equipment or operations

Scope 3: Other indirect GHG emissions (production of purchased materials and fuels, transport-related activities, product use by consumers…)

The main steps for the carbon footprint calculation and carbon reduction action plan establishment are: (A) setting boundaries, (B) Data collection, (C) Quantification, (D) Action plan (reporting + roadmap).

Step 1: Set up boundaries - what to include in the carbon footprint calculation?

Setting up boundaries starts with the organizational perimeter, which consists of deciding which legal entities, companies, or business units to include in the perimeter and how to account for their respective emissions. Then it follows with the operational perimeter, which includes selecting the scope of emissions to account for between scopes 1, 2, and 3, and identifying the relevant emissions categories within the different scopes. Last but not least, a baseline year needs to be determined, as well as a timeline for the Carbon footprint calculation.

Example of boundary-setting for carbon footprint calculation

Step 2: Data collection - which data to collect? Which data is available?

For each category of emissions to be calculated, company operational data needs to be collected and analyzed. The accuracy of this data is crucial, as the accuracy of the carbon footprint will directly depend on it. The data collection process can be complex, involving numerous departments within the company. It is vital to identify key personnel to drive the data collection process. Prior to conducting the data collection campaign per se, the accessibility of the data needs to be assessed.

Step 3: Quantification - calculation of the footprint.

Once the data collection is completed, the carbon footprint is calculated by multiplying the company’s operational data with emissions factors. Identifying relevant emissions factors is key to achieving a relevant carbon footprint. The emissions factors will depend on each sector, country, etc. There are no consolidated emissions factors databases in China at the moment. Therefore, companies need to research and identify the most relevant factors in the available local and global literature and standards.

Step 4: Carbon emissions reduction roadmap - how to reduce the carbon emissions along a timeline?

Following the quantification step, the company has achieved a clear understanding of its carbon emissions breakdown, and can then identify ways to reduce it. The different strategies should be consolidated in a roadmap leading ultimately to the company’s carbon reduction or carbon neutrality target. This roadmap should facilitate the implementation of the various carbon reduction strategies.

Action Plan: Company Level

An action plan will define the actions to take along a timeline to reach the company target regarding carbon emissions reduction. Here are some examples of actions companies can include in their action plan:

Recycled content raw materials: raw materials constitute a large share of final carbon emissions. Therefore, avoid emissions from raw material extraction by purchasing recycled content materials. Its carbon footprint would be ten times less than “raw” materials.

Supply chain: transforming from air-freighting to sea-freight or rail-freight, as their emissions are 700 times less than air-freight.

Refrigerant: Even if the quantity released from a refrigerant replacement for HVAC equipment might seem minor, the carbon footprint of refrigerants can be 2000 times more than CO2. Today, low-GWP alternatives are available, such as R32 instead of R22 or R410A, and R513A/R1234 instead of R134A.

Employee education: to truly implement these changes, employees must be on board with the goals and activities. Once carbon footprint objectives are set, training sessions should be organized as early as possible.

Green commuting: employees, visitors, and business travel carbon emissions could be reduced by promoting bicycles, online meetings, and car-sharing.

Action Plan: Site-Level

To mitigate their environmental impact, companies need to take action at the site level to reduce both the embodied and the operational carbon. The former can be reduced by treating the emissions related to construction materials, such as sourcing recycled content materials, sourcing local materials, or ‘minimizing’ the design. The latter is mostly associated with the energy consumed on-site during the operations. To minimize operational carbon, the approach is to reduce energy consumption as much as possible before offsetting the remaining emissions. Offsetting can be done by generating renewable energy on-site and relying less on the energy from the grid, which has a higher carbon content per kilowatt-hour of electricity. The offset can also be offsite, by sourcing renewable or low carbon content energy.

Energy consumption reduction can be achieved through combined energy efficiency solutions for the building systems, utilities, and industrial processes. If possible, maximizing the interaction with the local climate in different seasons can reduce HVAC consumption. In warm climates, options such as reflective roofing materials and ideal insulation thickness should be considered. Once the energy consumption has been reduced as much as possible, one can look at offsetting. The offset can be done on-site through renewable installation: Solar PV on the roof and parking canopies are popular solutions for commercial and industrial sites.

Carbon Offset

Finally, once all energy efficiency measures have been implemented, a way to reduce the global carbon footprint is to purchase Renewable Energy Certificates, invest in carbon offsetting projects, or trade carbon credits.

Green energy will be recognized in most cases with specific certificates, like Renewable Energy Certificates, as requested by the LEED Zero Carbon certification.

Offset projects should be certified under the VERA standard or GOLD standard to be recognized. This helps ensure an accurate count of CO2 equivalent the company has offset.

Carbon credits are not open to all companies in China for now: at the moment, only the big emitters such as power plants, and cement/steel factories would be able to take part in this scheme.

Companies’ Carbon Footprint in China

It may be daunting to reduce one’s carbon footprint in China, as main Scope 1 or Scope 2 emissions would come from electricity, which is coal-based in most provinces. Companies looking to stay and strive in the Chinese market must start working on carbon initiatives. As China’s Emissions Trading System (ETS) is not yet open to companies outside of the cement or steel industries, organizations must first assess their carbon footprint, and then rely on energy efficiency measures, renewables, and carbon offsetting measures.

In conclusion, to truly tackle excessive emissions and reach their goals, companies should have a dedicated task force, the support of specialists (internal or external) on such initiatives, train their employees, and set intermediary carbon reduction targets.

FAQ

What is the main challenge of carbon footprint calculation?

The process requires the involvement of the whole organization. To make sure the project stays on track, the company must define a clear timeline, a matrix of responsibility, and a steering committee. The steering committee would typically include the project manager of the carbon calculation service company, and a project sponsor and project manager on the client side.

Do electric vehicles reduce carbon footprint?

Electric vehicles do not emit direct emissions, therefore improving local air quality. However, their global carbon emissions depend on electricity production. In China’s case, EVs are not always a lower-emitting choice compared to petrol-fuelled vehicles.

Could one reduce the carbon emissions of existing facilities and newly built sites?

Yes. For existing facilities, you can only act on the operational carbon and conduct energy audits to identify (1) how to reduce the energy consumption and (2) find out how to better operate them and optimize energy consumption. For new facilities, you can reduce both the embodied and the operational carbon from an early stage.

Will I see ROI for emission-reducing actions?

The ROI is not always evident while working on environmental impact mitigation. Solutions generating energy savings often have an ROI, but their attractiveness depends on the local energy price (relatively low in China, for example). However, more and more clients and investors require companies to take action on their carbon emissions – meaning there is a cost of not taking action.

What is the main obstacle to site-level action?

Awareness of users and employees. To cope with this obstacle, companies must take action to train employees on such topics and create dedicated systems and processes. For example, for existing facilities, energy audits can be combined with ISO50001 implementation.

Source:Ticker 2022 Summer

Like