公司名称:纬湃科技投资(中国)有限公司

项目名称:电动轴驱系统EMR4

奖项类别:创新可持续产品

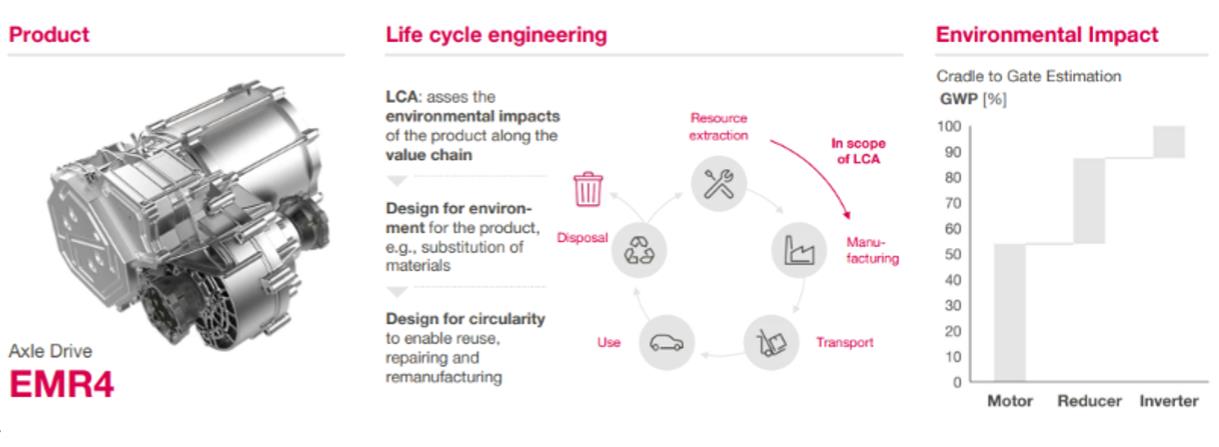

产品/服务 介绍

纬湃科技, 市场领先的现代驱动技术和电动化解决方案提供者,将会为一家国际化的汽车制造商提供B/C 级别的电动轴驱系统EMR4. 整个生命周期的定单约3百万套,和20亿欧元的销售额。该产品将于2024年6月在纬湃全球3家工厂进行投产。

EMR4 是纬湃科技的第4代电动轴驱产品,它建立于纬湃科技成功电驱动产品开发和生产经验,这是一款高度集成的三合一驱动平台,包含电机,功率电子控制系统和减速器,s适用于400V 电压平台,功率160kW。

通过多目标的优化措施,新技术的使用以及应用先进的生产工艺,这款全球打造的EMR4平台尺寸更为紧凑,更为高效,动力更强。 例如,碳化硅功率器件的使用,对效率提升产生了重要影响。

循环经济实践阐述

生命周期阶段概述

设计阶段:

Magnets: change of process of magnet fixation in the rotor: EMR3 = glueing, EMR4 = culking

Improved weight: EMR3 = ~77kg, EMR4 = ~66kg at same power of 150kW --> benefit: saving of magnets, aluminium, copper results in lower CO2 emissions of raw materials

Use of recycled aluminium with much better GWP per kg

生产阶段:

CO2 neutral prodution.

Local sourcing

Low Scrap during production

使用阶段:

Efficiency increase of 3...5% from previous generation to EMR4

Lower weight of EMR4 vs. EMR3 results in lower net vehicle weight

回收与再生阶段:

No potting --> separation of components possible

Inter-cover can be removed and electronics can be separated either for repair or recycling

更多产品/服务亮点

Extended platform to even better life cycle assessment

As a result of Life Cycle Engineering, the fourth generation of its fully integrated electric axle drive platform (EMR4, Electronics Motor Reducer) is being broadened by a new option to enable an even better life cycle assessment: A new rotor without permanent magnets is now part of the platform development. This rotor forms the core of an externally excited synchronous machine (EESM), which works without rare earths. This reduces the rotor costs, and it avoids the carbon footprint that comes with mining and processing the ores.

Global Manufacturing footprint

3 locations to serve global electrification market: Incheon (Korea) Brasov(Romania) Tianjin (China)

Supply Chain Management

Localized supply chain to reduce CO2 generated from transport, boost local economy