Company Name: MAHLE Holding (China) Co., Ltd.

Project Name: Superior Continuous Torque (SCT) E-motor

Award Category: Innovation Sustainable Product

Product / Service Introduction

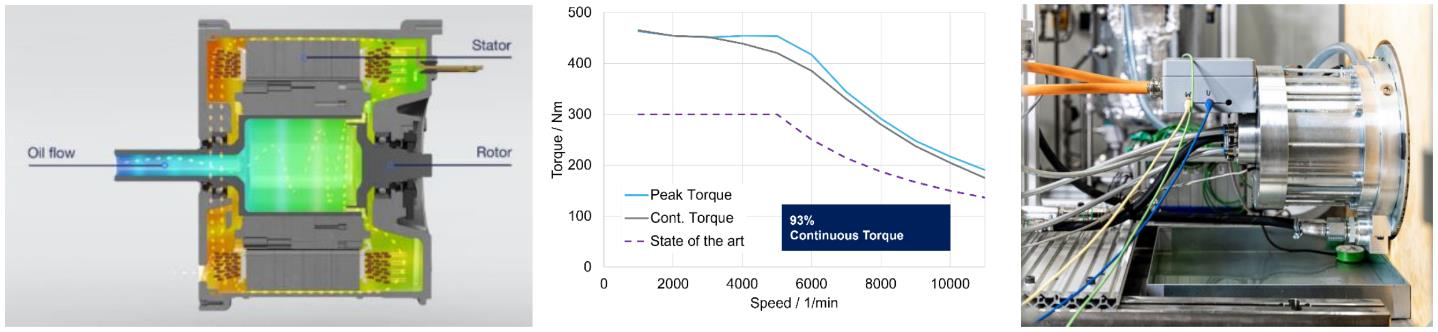

MAHLE superior-continuous torque (SCT) motor, which is based on the integrated direct oil cooling technology, of which the end winding is soaked in oil and the heat generated in the motor is quickly taken away due to unique flow channel design and sealing design. The integrated direct oil cooling technology enables MAHLE SCT motor to achieve consistently high power output, achieving the best in-class ratio of continuous to peak torque of 93 % and a continuous power density of 7.1 kW / kg. Compared to conventional water-jacketed cooling motor, MAHLE SCT motor enables an advantage in material cost and light weight as well as durability, and a lighter motor requires less material during manufacturing.

Explanation of Circular Economy Practice

Generally, a motor with state-of the art water jacket cooling technology typically requires 8096 larger than MAHLE SCT motors to achieve the same continuous torque, and it can only deliver high power only for a short period of time and require derating of output power to appr. 40 to 60 percent of peak performance in continuous operation. Without power reduction, the waste heat generated in the component would lead to critical component temperatures and significantly reduce product lifetime or even cause damage. The SCT technology enables long-time high power performance and more compact structure with more than 40% amount of material reduction. During the production and application of SCT motors, certain CO2 emissions and other environmental impacts can also be reduced. SCT motors can not only reduce the cost, weight and volume of the product itself, but also reduce the environmental impact of the entire product life cycle, thus SCT motors can be a sustainable solution for the electrification of future vehicles. In addition, SCT technology, combined with the magnet-free motor IEESM also developed by MAHLE, achieves similar performance comparable to current permanent magnet synchronous motors and is independent of rare earth materials.

Overview of Product/Service Lifecycle

Product Design:

The SCT technology can be applied on any electric powertrain.

Production:

Compared with the similar products

Reduce 40% of material

Reduction of magnet material

Reduce CO2 emissions in production

Reduce the carbon footprint

Useage:

Increase the motor efficiency

Reduces the energy consumption of the vehicle

Recycling and Recovery:

100% recoverable metal materials.

No Toxic and hazardous substances are used.

More Product / Service Highlights

The SCT motor can fulfill essential requirements of demanding scenarios, such as rugged mountain roads, repeated sharp acceleration.

The SCT motor is suitable for various types of passenger cars, commercial vehicles, and even construction machinery and traction equipment.

The integraled cooling concepe not only ensures better robustness system, but also makes use of waste heal.

Like 35