Company Name: Volkswagen Automatic Transmission (Tianjin) Co., Ltd.

Award Category: ESG Performance

Company Size: Medium-sized Enterprise Group

Environment

Climate Change:

"GoToZero " is a vision proposed in the Volkswagen Group’s 2025 strategy, which reflects the Volkswagen Group’s determination to take "environment" as the leading role model for its production strategy. In 2019, VWATJ adopted VWATJ's environmental protection strategy based on the group's strategy and proposed the "Zero Impact" strategy. Based on this strategy, we are committed to reducing the impact on the environment as much as possible during the production process to maintain ecological integrity and create a positive impact on society. Compliance with environmental regulations, standards and a positive commitment to environmental protection are the foundation of our actions.

At the same time, in order to further deepen the pilot construction of carbon emission trading in Tianjin, promote annual compliance, and actively dock with the construction of the national carbon emission trading market, VWATJ joined the Tianjin carbon emission trading list in 2021, becoming one of the first 192 enterprises to comply with the treaty. So far, the implementation of carbon emission compliance in 2021 and 2022 has been completed. In 2022, the direct CO2 emissions from natural gas, gasoline and diesel were 1,071 tons, and the indirect CO2 emissions through electricity and heat were 225,882.9 tons.

In order to achieve the purpose of the vision, the company organized a number of activities to encourage participation, such as "Green Factory Tour", "C-UEP", etc. The event adopts videos, on-site explanations, exhibition panels, small gifts and other forms to promote the concept and measures of energy conservation and environmental protection. In 2022, 16 measures such as LED, heat recovery, and rooftop solar energy will be adopted, and CO2 emissions are expected to be reduced by 19,618 tons throughout the year.

Natural Resources and Energy:

The company is committed to minimizing the impact on the environment in the production process. In 2019 clean production audit and the 2020 energy audit, the company established a sound energy management system, and made clear provisions on measurement data collection, graded management and use of measurement equipment, and storage. Meanwhile, we aim to reduce the consumption of non-renewable energy from the perspectives of energy conservation and energy substitution. For example, in 2022, through the adjustment of the washing machine control device, the equipment can realize the function of automatic induction start and stop, accurately calculate the use time of the equipment, and improve the energy efficiency to save 310MWH of energy consumption throughout the year.

In the same year, solar photovoltaic power generation modules were installed on the roof of the DQ plant and the newly built carport, and the high-voltage 10kV was connected to the grid for power generation. The installed capacity of the project is 12.28274MWp, of which the roof usable area is about 215600m2, the carport is about 5000m2, and the consumption mode is spontaneous and self-consumption, and the surplus electricity is on the Internet. According to the total installed capacity, inclined surface irradiation, system efficiency and attenuation of the nominal efficiency of photovoltaic modules, it is expected that the annual renewable energy power generation can reach 15500MWh.

In addition, in order to monitor the energy consumption of equipment more accurately, the company adopts BMS system monitoring and establishes an EMS management system, which can not only monitor the energy consumption of each workshop, but also monitor the real-time energy usage of key energy-consuming equipment in the pilot area. Precisely exploit energy saving potential.

Prevention of Pollution :

The company has advanced equipment and technology, excellent product performance, and attaches importance to green and low-carbon environmental protection publicity and training; Strict requirements for suppliers to achieve harmless raw materials; Implement various initiatives to reduce raw materials; Strictly control pollutants and achieve clean production; Strictly implement waste classification management to realize waste recycling.

Main environmental protection measures:

Installed various waste gas treatment facilities, and the exhaust gas is collected and treated through the exhaust cylinder after organized discharge. Related environmental protection facilities include dry filter cartridge dust collector, cyclone dust removal + wet dust collector, oil mist purification device, activated carbon adsorption device, two-stage composite glass fiber plus activated carbon and high-efficiency oil fume purifier.

The enterprise realizes the diversion of rainwater and discharges rainwater into the municipal rainwater pipe network. The wastewater generated in the production and operation process of the enterprise mainly includes cleaning waste liquid, waste emulsion, ground scrubbing wastewater, tail water and domestic sewage generated by the circulating cooling system.

The company regularly carries out green manufacturing related training and publicity every year, and encourages all employees to participate in the construction of green factories through knowledge competitions, special training, energy conservation publicity month, environmental protection publicity month, safety production month and other forms and channels, which is in line with the purpose of green factory education and training. At the same time, the company has established an energy experience area in the DQ plant training center. The experience area is equipped with 4 energy simulation experience stations, as well as waste sorting area and DIY area. Employees and visitors who participate in the experience can promote the concept of energy conservation and emission reduction of the Volkswagen Group through actual participation, publicize the knowledge of energy conservation and environmental protection, and cultivate employees' awareness of energy conservation.

Meanwhile, the company actively responded to the overall arrangement of Volkswagen Group China and took the lead in launching a green factory tour within the group. The Green Factory Tour aims to convey to employees and the public the importance of sustainability and creating a green future, inviting guests to visit the plant to learn about the Volkswagen Group's sustainable production technologies and how to minimize energy and resource consumption and minimize the impact of waste emissions and greenhouse gas emissions.

Other Actions Taken for Environmental Protection:

Initiative for Biodiversity conservation: In 2022, VWATJ has finished the project of planting trees in the landscape with 410 local Sophora japonica and 1729.20㎡ Euonymus japonicas been planted.

Social

HR Development and Engagement:

Employee health:

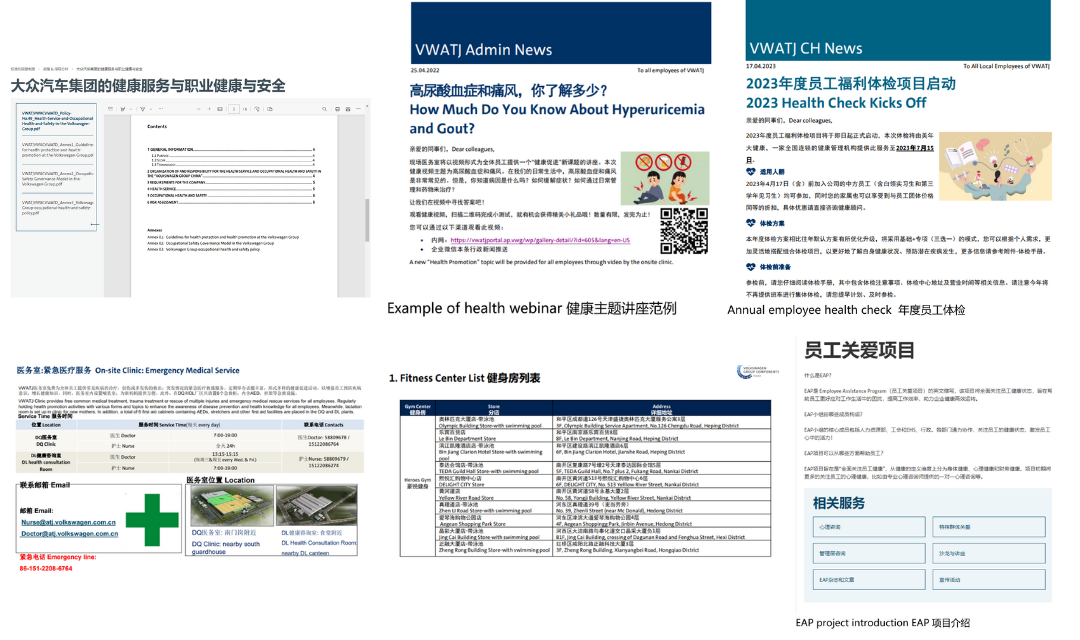

Clear policy on health service and occupational health and safety

Internal clinic is set up. Regular first-aid training is offering to employees.

We offer annual free health check and conduct online and offline themed health webinar for employees.

We promote EAP program in the plant and offer online consultation and offline workshop to take care of the mental health of our employees.

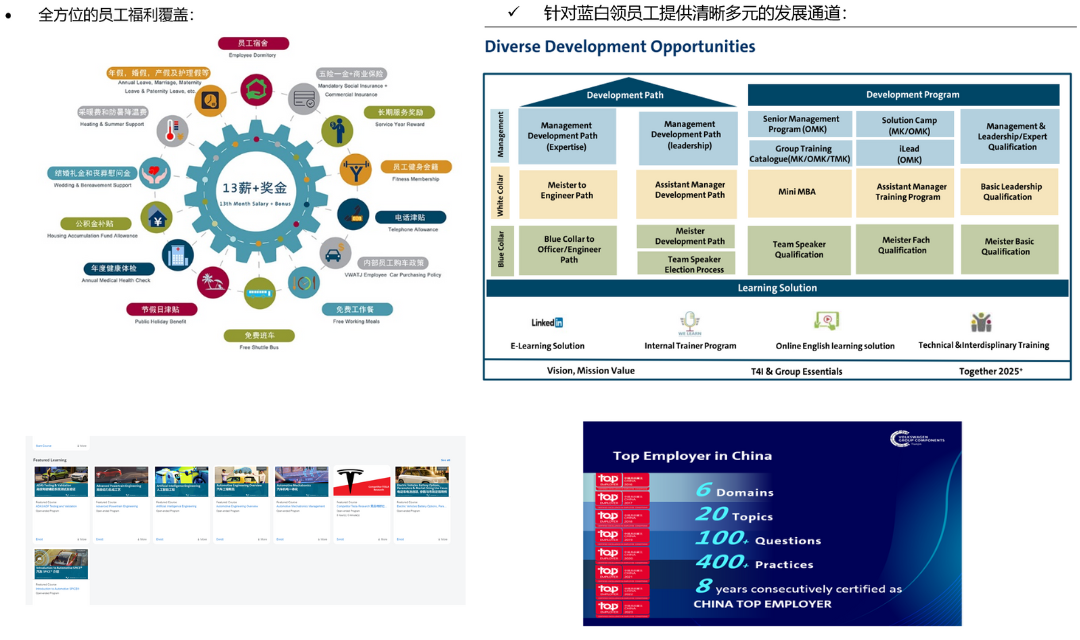

Comprehensive employee benefits

Transparent and clear career development path

Clear and diverse development opportunities for both White collar and blue collar employees.

Offer online learning platform to empower employees during the business transformation.

VWATJ has been certified as China Top Employer for 8 consecutive years by Top Employer Institute.

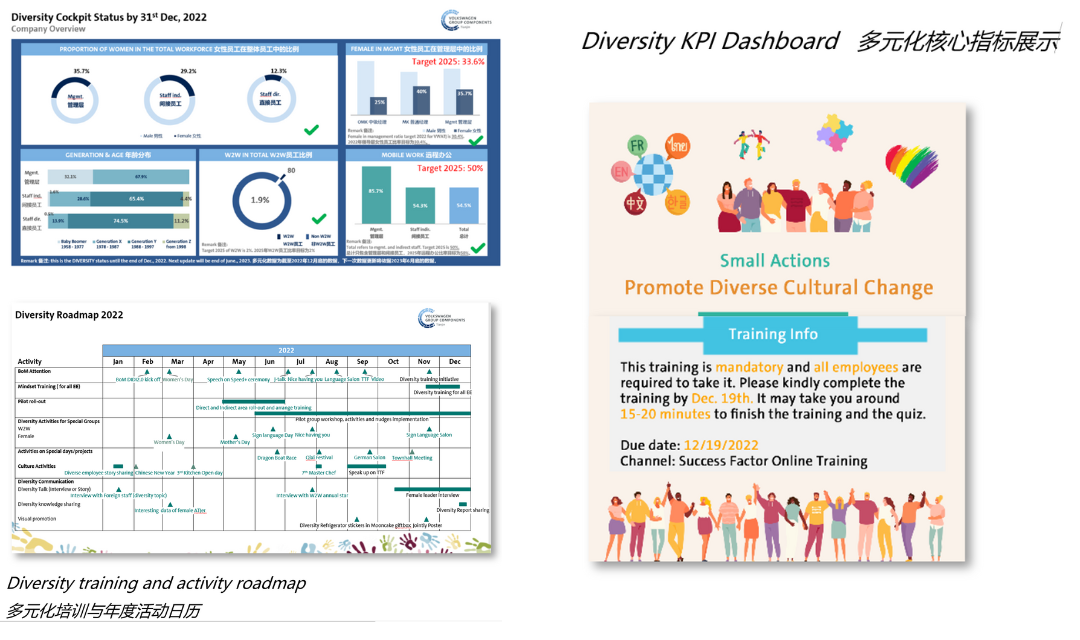

Diversity,Equity and Inclusion :

We live diversity” is one of the VW group essentials and also a key culture project in VWATJ

We have defined and communicated our own DEI commitment

We use female management ratio and Mobile work ratio as the main DEI KPI.

We have specific program to recruit and develop disabled people, support female employees and young talents.

We conduct annual online Diversity training to all EEs and implement DEI activities around the year.

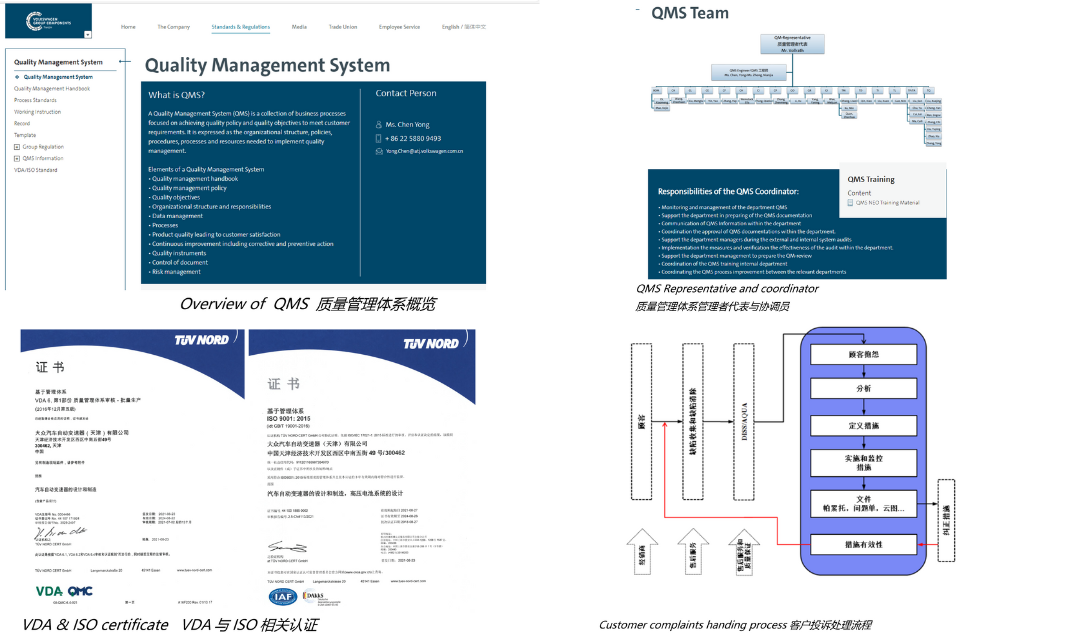

Product Liability:

We have holistic QMS to guarantee the product safety and quality control (including QM handbook, process standards, working instruction, etc.)

We have defined QM representative as the key responsible person to ensure product safety and set up QMS coordinator in each department.

All the characteristics that influencing product safety are recorded in product technical document, such as drawing or technical delivery condition and test specification. Related information will be separately checked and recorded.

We have the QM certification of VDA 6.1 and ISO 9001 and keep improving our QMS based on them.

We have specific process to track customer feedback /complaints and conduct relative improvement. The customer satisfaction rate of our key customers are always more than 90 with the full score as 100.

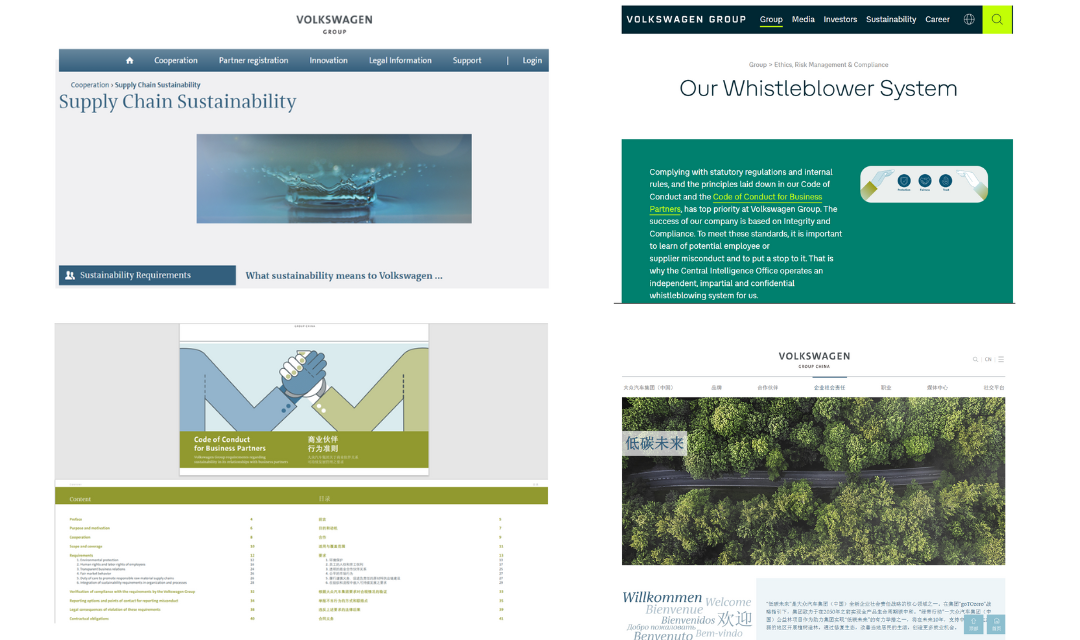

Supply Chain:

Supply Chain ESG Strategy, Including but not limited to the following:

The Volkswagen Group Sustainability Rating (S-rating) system includes supplier selection, evaluation, training, and etc. Web: S-Rating

VW require suppliers to follow <Code of Conduct of Business Partners>

"goTOzero”, aim to achieve carbon neutrality in the whole Product lifecycle by 2050.

Whistleblower System, to report potential violations.

Supplier selection and evaluation mechanism: The sustainable development rating system is responsible for selecting and evaluating suppliers.

Supplier training: We offer regular training programs for suppliers.

Community Engagement:

As our company mission states, “We take on responsibility for the environment, society and our people”, the focus of VWATJ CSR is climate protection, working opportunities for people with disabilities and special care for children and the elderly. VWATJ employees are becoming increasingly involved in CSR activity alongside the company. https://www.vwatj.com/zh-hans/people-culture/our-csr/

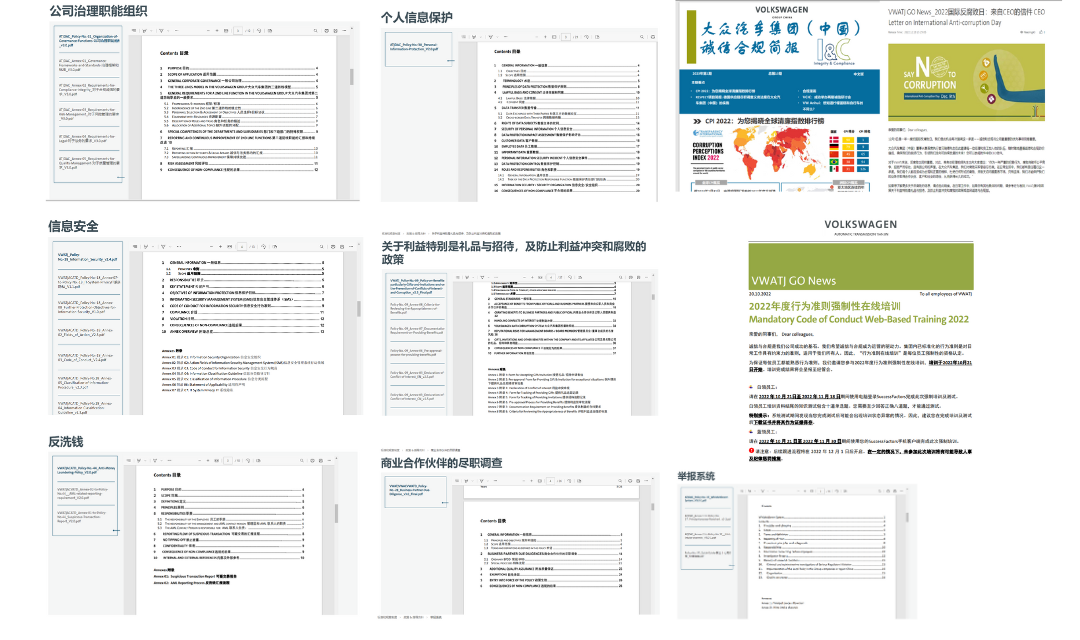

Corporate Governance

Governance Organizational and Mechanism:

The company has defined clear organization of governance functions, including but not limited to governance framework and standard, requirements for compliance & integrity, risk management, legal and quality management.

The company has clear policy for personal information protection (incl. customer information and employee information) and information security, with clear responsible persons and actions.

The company has defined clear policy on prevention of conflicts of interests and corruption, anti-money laundering, business partner due diligence, and provides transparent and open whistleblower system.

The company conducts compliance and integrity promotion every year on regular basis. Compliance training is a mandatory part of New Employee Orientation, and mandatory training of Code of Conduct is carried out every year for employees. Compliance training and promotion are also available to our suppliers and business partners.

Innovation Sustainability:

ESG in company business and strategy:

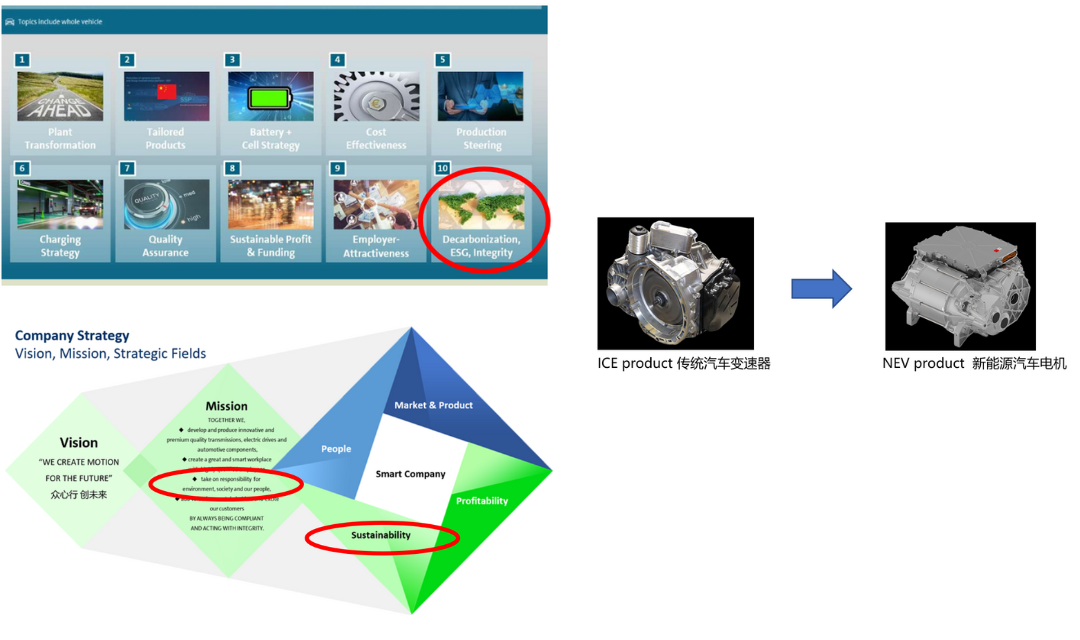

ESG is one of the VW Group China Component top 10 programs. As one of the VW Component companies in China, VWATJ also puts ESG as our business priority to support the program.

One of our company mission is “we take on responsibility for environment, society and our people. And “Sustainability “has been defined as one of our strategic fields.

Transformation from ICE product to NEV product :

In line with the VW Group transformation, we are steadily transferring our product portfolio from ICE to advanced NEV drive. It is estimated that in 2026 our NEV product volume will reach the same level of ICE product. All the NEV products will be used on the VW China NEV auto. The NEV transformation will bring positive influence to the environment and tremendously reduce the CO2 emission.