Introduction

German companies have an extensive experience in making their productions and value chains environmental-friendly. This mindset has developed over decades, as companies sought out holistic solutions and developed them over time. German companies are keen to bring their knowledge and expertise to global markets, to adapt and to develop them further with local partners.

The German Chamber of Commerce in China strongly appreciates China’s commitment to achieving the decarbonization goals. The Chamber sees strong potential for German companies’ contribution for the following reasons:

1.The large number of German companies: Around 6,000 German companies operate in the Chinese market to date.

2.German companies are stable and reliable partners: Half of the German companies have been physically present in China for more than 15 years³.

3.German companies are already at the forefront with their environmental-friendly technologies or when adhering to environmental standards. According to the German Chamber’s recent Business Confidence Survey almost half of the German companies in China consider China’s upcoming '30-60' decarbonization goals as an opportunity for their products, services, technologies, and solutions, showing that German companies have a lot to offer. German companies are already in the process of becoming greener – with two thirds of German companies having measures in place.

However, in a challenging market environment, German companies require the support from the Chinese government to unlock their full potential in terms of decarbonization. In order to better support their activities and, hence, contribution to the Chinese market, the Chinese government needs to have a better understanding of German companies' existing efforts and methods to reach China's decarbonization goals.

German Companies’ Contribution to China’s Decarbonization Drive: Products, Services, Technologies, and Solutions

Many German companies in China already have products, services, technologies, and solutions in place which can contribute to China’s decarbonization goals. The German Chamber’s recent Business Confidence Survey shows that nearly one third (31%) of the German companies are already developing carbon-reducing products and services or are adapting their existing portfolio accordingly.

In some of the following examples, CO2 emissions are reduced by half by using these products. Although this paper only gives a glimpse into the achievements and contributions of German companies, it becomes nevertheless visible that just by considering the products of these companies, a tangible step towards China’s carbon neutrality goal can be made.

What are the products, services, technologies, and solutions German companies are strong at? This paper shows examples which fit very well into the goals that the Chinese government has set not only for 2030 and 2060 but also for 2025: By 2025, the share of non-fossil fuels in total energy consumption will reach around 20%. Energy consumption and carbon dioxide emissions per unit of GDP will drop by 31.5% and 18% respectively.⁵ German companies have been developing various advanced solutions in both areas – energy consumption and emissions – and are continuously improving them. Hence, German companies have a lot to contribute.

In the following, specific examples of technologies that German companies have to offer are outlined. They directly connect with the mid- and long-term goals and the roadmap China has set for achieving the decarbonization goals. These cases are by far not exhaustive. They, however, show the stable, profound and high-quality character of German companies’ offerings and portfolio.

Energy-saving and Emissions Reduction Technologies - German Companies’ Solutions

China’s Goals & Plans

Accounting for 70 to 80% of global CO2 emissions, energy plays a significant role in global carbon emission reductions. Here, China’s Action Plan for Carbon Dioxide Peaking before 2030(“Action Plan”). specifically names that energy saving standards should be reached by focusing on equipment such as pumps, compressors, heat exchangers and industrial boilers. In February 2022, NDRC and the National Energy Agency jointly released the a document regarding China’s energy transition toward net zero⁸ under the 1+N policy framework.

German Companies’ Solutions

To reduce energy and waste for more profitable manufacturing processes, it is essential to optimize energy efficiency by replacing or upgrading the adapting processes or equipment using energy-saving and carbon-reducing technologies. German machine manufacturers and their expertise can contribute with energy-saving products and process optimizing technologies to different industry segments in the Chinese market.

German companies provide heat treatment systems with low pressure vacuum carburizing (LPC) and high-pressure gas quenching (HPGQ) heat treatment processing and services in China to the automotive, energy, medical equipment, aerospace industries among others. The heat treatment equipment can achieve higher temperatures with a shorter production cycle, saving energy, reducing emissions and consuming less resources.

Companies also provide heat pump systems using renewable energy to supply, for example, 25,000 households with heat and with this avoiding 100,000 tons of CO2 per year. They also offer mechanical and electrical pumps for oil, water and air that reduce pumping losses for combustion engines and electric vehicles. The application reduces the CO2 emissions of the combustion engines and reduces power consumption of electric vehicle batteries – reducing battery power consumption and charging which all emits CO2.

Other companies offer compression technology with heat recovery for a CCS (carbon capture and storage) project of a cement plant to reduce 400,000 tons CO2 per year. Companies also develop valves which can reduce CO2 emissions, such Exhaust Gas Recirculation valves (Example: max. reduction CO2 2g/km, coolant valves – max. reduce CO2 3g/km (w/coolant pumps), variable valve train – max. reduction CO2 7g/km).

Companies also provide energy-saving industrial boilers that use clean fuel and clean combustion technology, with thermal efficiency exceeding 94% and attain grade 1 energy efficiency standard as well as energy-saving transformers that have a high storage capacity and are high-voltage, are noise controllable, degradable, and recyclable with grade 1 energy efficiency standards.

Many German companies provide machines for automation or processing optimization. In addition to companies successfully helping China in its vast automation efforts of large factories, another specific example for processing optimization are sugar processing machines which save energy during sugar cooling and drying processes. Reduced air consumption for these processes is achieved, and exhaust air from the cooling system can be used for drying, thus thermal energy is saved.

German companies are also well represented in the packaging industry. One of the various solutions for reducing the carbon footprint are film stretching lines, especially for the FMCG packaging industry and new energy-related industries. Film stretching lines decrease the raw material usage, avoid energy-intense pre-drying of raw materials and minimize the energy consumption during film production. There are new line concepts for serving electromobility (battery separator film production) and the solar industry (conventional solar panels or lightweight and versatile flexible solar panels). Compared to levels in 2000, Nearly 50% reduction of the energy consumption for film stretching lines can be achieved.

Lightweight Solutions

China’s Goals & Plans

For reducing carbon emissions by 18% by 2025, lightweight solutions are key for making products lighter and reducing emissions in all kinds of industries. In China’s 14th Five-Year Plan, a reference to light alloy materials in the aviation industry is also made.

In China, demand for lightweight solutions is increasing in all kinds of industries such as aerospace, wind energy, rail transportation, as well as automotive. In the automotive sector, lightweight solutions do not only satisfy requirements of safety and comfortable driving but also help to meet carbon emission reduction targets: the lighter the material, the fewer the emissions.

German Companies’ Solutions

German companies have been active in lightweight solutions for many years. The “Lightweight Construction Strategy”– initiated by the Federal Ministry for Economic Affairs and Climate Action in 2021 and developed together with 350 German companies and academics – ensures continuous innovation in sustainability for grasping the potentials of lightweight solutions for climate protection and carbon neutrality. This makes Germany a successful lead provider of innovative lightweight solutions across the world. At the same time, it puts German companies, especially SMEs, in a strong position to contribute to carbon neutrality in various markets – especially through their presence and engagement in China.

For example, German companies are strongly active in the production of lightweight composite materials (e.g. recyclable PET foam and balsa wood) which can be applied in various industries such as building & construction, automotive, aerospace, rail, and marine. Another effort is replacing steel with plastic, such as gear and functional parts. Other lightweight solutions include products made from aluminum alloys.

Hydrogen Technologies

China’s Goals & Plans

Also in China’s transportation sector, green and low-carbon transportation modes should be developed in a faster way. By 2030, the share of newly sold vehicles fueled by new and clean energy will reach around 40%, and carbon emission intensity of commercial vehicles measured on the basis of converted turnover will be cut by about 9.5% compared to 2020. New and clean energy includes electricity, hydrogen fuel, and liquified natural gas.¹⁰ China’s newly issued Medium and Long-term Plan for Development of the Hydrogen Industry (2021-2035) also focuses on the role of hydrogen in the decarbonization of the national economy. It is outlining a hydrogen power system including transport, energy storage and industries by 2035, opening up new opportunities for German solutions. By 2025, the central government aims to increase

the number of hydrogen-powered fuel cell vehicles (FCEVs) to at least 50,000 with an annual production of renewable hydrogen between 100,000 and 200,000 tons.

German Companies’ Solutions

German companies provide, for instance, type IV hydrogen cylinders and vehicle systems for fuel cell electric vehicles and hydrogen storage, transportation, and distribution. This also includes solutions to the key challenge in the commercialization of fuel cell electric vehicles – how to store highly volatile and low-density hydrogen safely and cost effectively. Another example is a hydrogen fuel cell center operated by a China-based German company leading in this field. Hydrogen fuel cells are a promising technology due to their light weight, short refilling time and zero emissions and are especially suited for use in medium and heavy commercial and passenger vehicles.

Furthermore, mainly through electrolysis technology, hydrogen can be produced from renewable energies. Several German companies can provide components and system services as well as complete electrolysis plants. Besides the established technology of alkaline electrolysis, so-called Proton Exchange Membrane (PEM) electrolysers make up an emerging share of the market. Regarding industrial applications, hydrogen is increasingly used as a reducing agent in steel-making, and German companies can offer know-how for respective production processes.

Consulting, Evaluation and Energy Management Systems

China’s Goals & Plans

In the Action Plan it is also set out that the standards for the development of environmentally friendly and low carbon development of industries will be improved, including standards for calculating, reporting, and verifying carbon emissions from major enterprises, and exploring ways to set life cycle carbon footprint standards for major products.

Also, one of the priorities in the Action Plan is to keep energy consumption under control in terms of both volume and intensity. Therefore, raising capacity for managing energy conservation and assessing a project’s energy use as well as carbon emissions is seen as crucial. Systems for online monitoring of energy consumption should become more sophisticated and be implemented more widely. Especially energy-intense enterprises need to set up energy management centers. The use of certification to improve the level of management over energy consumption is also encouraged.

German Companies’ Solutions

German companies in China can support not only with software solutions to monitor energy consumption and optimize the energy consumption processes, they also support with certifying an energy management system standard ISO 50001. They can, for instance, support in establishing a customized measurement and monitoring concept, easily connecting new and existing sensors, offer system integration, optimizing and efficient solutions. Another contribution is the provision of hardware and software applications for safeguarding process plants, where uncontrolled situations often lead to large quantities of emissions including CO2 emissions.

German companies also provide solutions for entire demo projects, for example smart energy villages. This include large and all-encompassing energy management platforms, and it is estimated that such a village can save energy consumption by 10% and reduce CO2 emissions by 50 to 55%.

Green Buildings

China’s Goals & Plans

Green buildings play a significant role for the formulated action for peaking carbon dioxide emissions in urban and rural development, where green and low-carbon design concepts and materials are promoted. According to the plan, all newly constructed buildings in urban areas are supposed to meet green building standards by 2025. Another document has been released last October on urban and rural development according to which green buildings are the top priority in the section of transformation of urban and rural development models.

German Companies’ Solutions

In the construction of sustainable green buildings, companies from different sectors need to be involved. In Germany, 1,500 architects, engineers, construction planners, building contractors and other companies, organizations and individuals – basically covering the entire value chain – are assembled in the German Sustainable Building Council (DGNB). Since being founded in 2007, they accumulated a huge and interdisciplinary knowledge pool.

Likewise, German companies in China engage in this area, reducing the overall impact of the built environment throughout its life cycle. During planning, design, construction, operation, maintenance, renovation, and demolition they pay strong attention to efficiently use energy, water, and other resources, to protect occupants’ health and improve employee productivity as well as to reduce waste and pollution. Also, German companies are leading in developing and applying construction products and components, for example for providing solutions for energy-efficient building envelopes, building insulation and HVAC systems.

Circular Economy

China’s Goals & Plans

The Action Plan aims to push ahead with the development of the circular economy and the efficient utilization of resources in China. Among others, the focus is on re-using bulk solid waste and household waste as well as the improvement of recycling networks for used materials and waste, such as auto parts remanufacturing. The recycling of residual heat and pressure, of waste gas, liquid, and slag from industrial processes as well as the application of centralized gas and heating supply should be expanded in industry parks among others. By 2030, all key industry parks at central and provincial level should be upgraded to support circular operations. Also, the sorting system for urban household waste is aimed at covering all cities in China. Additionally, a five-year plan devoted to the circular economy has been released.

German Companies’ Solutions

In the portfolio of German automobile manufactures, examples for vehicles that are optimized for closed material circles and achieve a 100% use of recycled materials can be found. The range of parts which can be remanufactured auto parts is also constantly increasing, including engines, electrical power steering gears, head units, and mechatronics. Remanufacturing of used engines and other product groups not only cuts costs (for instance 30% per component), it also can reduce energy consumption by 80%, while the reduction in resource use is even higher.

Since German companies are strong in the machinery sector, they also offer a comprehensive range of recycling machines for the efficient processing of a wide range of recyclable and waste solid materials. This includes the pretreatment, size reducing, re-shaping and final sorting in reusable and homogenous raw materials. In the product portfolio are recycling machines and plants for refrigerators, washing machines, home appliances, televisions, electrical cables, for lithium battery recycling, for automotive shredder residues and tire recycling, for recovery of slags and other valuable reusable materials. Recycling machines and plants for municipal solid waste and for reclaiming metals are also produced. Also, German companies offer recycling machines for an efficient and energy saving treatment of agriculture, food and forest waste and transforming it into biogas and fertilizer.

German Companies’ Contribution to China’s Decarbonization Drive: Measures to reduce the Carbon Footprint

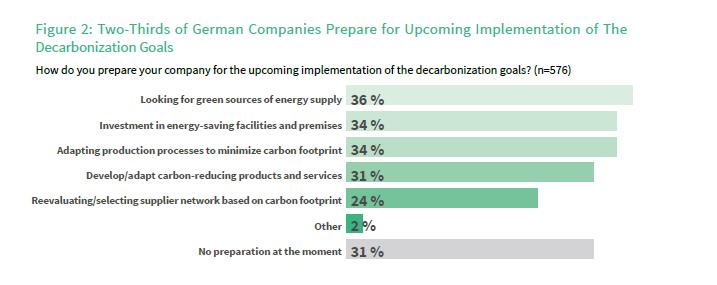

German companies in China have been committed to protecting the environment and are continuing their efforts towards achieving carbon neutrality. According to the Chamber’s recent Business Confidence Survey, more than two thirds of German companies have already been taking measures for reducing their companies’ carbon footprint in China. These companies are preparing for carbon neutrality in various ways, including looking for green sources of energy supply (36%), investment in energy-saving facilities and premises (34%), adapting production processes to minimize their carbon footprint (34%), and reevaluating their supplier network based on carbon footprint considerations (24%). In particular, the automotive and chemical industries work actively with suppliers and energy providers towards decarbonization. Only 31% have not started to prepare (see Figure 2).

Major measures that German companies have taken to implement the decarbonization goals are summarized along these categories (with “Green Factory Certificates” as an additional item).

Advocating for Unlocking German Companies’ Full Potential

In order to contribute to China’s decarbonization goals in a more targeted way and for better tapping the potential of German companies in the future, the German Chamber in China advocates for the following towards the Chinese authorities:

Energy Security & Green Energy Availability

For years, German companies have been keen on buying green energy as an alternative to conventional energy sources. With the power shortages in autumn 2021, energy availability and energy security have become a strong a concern. This accelerated the push towards installing sources of green energy. Companies still question whether there is enough energy available in general so that companies’ operations are not interrupted. Also, questions arise on whether there are enough green sources available for companies to move forward on achieving their company’s carbon neutrality targets.

More and more companies now generate or intend to generate their own renewable electricity and contribute to the general power availability. Incentives or supporting policies could help to make related investments happen. Furthermore, clarity is needed how a possible electricity contribution would be taken into consideration by the local authorities in case of another round of power shortages.

Green Electricity Certificates

For German companies operating in China but also internationally it is important to make their contribution to the environment associated with renewable energy generation transparent and to have a market-based renewable energy mechanism in China. Here, the “Green Electricity Certificates” (GEC) system plays an important role.

The current GEC system, however, is not fully recognized in international markets and vice versa, and the pricing is high compared to international standards. Foreign and Chinese companies alike would greatly benefit from a harmonized and internationally recognized system.

Unified Standards in Lifecycle Assessment

The Lifecycle Assessment (LCA) method plays a significant role to assess the effect of a product’s carbon emissions and to evaluate resource consumption and environment emissions throughout the entire lifecycle of a product. For instance, in the automobile industry, a vehicle’s lifecycle starts with the raw materials extraction and ends with end-of-life recycling.

Currently, there is no mandatory regulation enforcing LCA and therefore no standardized assessment and much needed standards are still in the formulation process.

Moreover, to conduct LCA required data is missing. The carbon emissions of each step need to be taken into consideration, such as data on the transport of components to automobile manufacturers and the delivery of a vehicle to consumers or on the scrapping and recycling the whole vehicle. According to EU standards, it is necessary to know the data of energy consumption for each step.

Harmonization of Certified Carbon Emissions Reductions

Although German companies’ emissions are already low, there are still emissions which cannot be avoided. China’s carbon emission credit scheme is currently on hold and the scheme’s standards differ from European and international standards (e.g. for credits generated from forestation projects). It is unclear when credits will be available and whether China’s emissions credits will be recognized internationally. To assure the quality when offsetting projects, projects should meet certain criteria, e.g. compliance with standards, credibility, site selection, project size, the contribution to achieving the United Nations Sustainable Development Goals and CO2 saving. The criteria must be precisely quantified and provable.

Timely and Transparent Communication of Policies

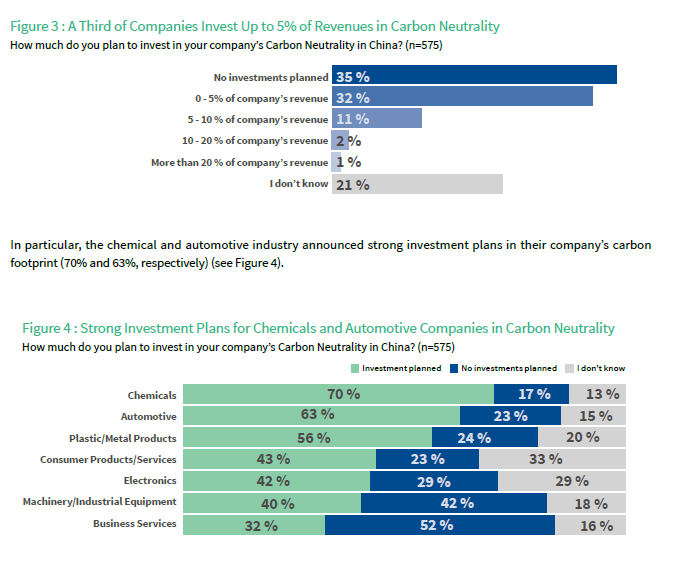

German Companies intent to continue to invest into carbon neutrality. One-third of German companies in China already invests up to 5% of their revenues into carbon neutrality. One percent of surveyed companies invest even more than 20% of their company’s revenue.

If German companies continue to invest and in which direction their investment goes, often depends on how transparent the relevant policies are and how clearly they are communicated. Also, it might depend on policies being timely communicated so that German companies can consider them in their strategic decision making and planning.

More than half (57%) expect rising operation costs due to stricter environmental regulations and energy pricing at the same tim. In terms of regulations, better foreseeable and calculable costs would greatly help German companies.

Moreover, the Chamber’s recent survey shows that those companies which expect higher operating costs rather consider the development of their industry worsening, the participation in innovation not as much as a business opportunity, and rather do no plan to invest or even decrease investment in the coming two years. Furthermore, they mostly see relocating facilities and environmental protection requirements as challenging. This shows that transparency is necessary in terms of requirements but also for bringing more certainty to companies, for instance, assurance of not being forced to relocate in the future.

Engagement and Cooperation on a Level-Playing-Field

As envisaged by the Action Plan, Chinese authorities should encourage companies to take proactive steps to meet the needs for a low-carbon development. For German companies this encouragement would not be necessary as they are already strongly committed to participating in China’s decarbonization drive.

However, a large part of German companies are SMEs, and very often they are “hidden champions” in their niche markets. It can happen that SMEs have the much-needed technologies and solutions to offer but are still largely unknown locally. Therefore, the Chamber encourages governments all over China to actively reach out to their local SMEs and identify their “hidden champions”.

Moreover, German companies in general need a signal that their contribution is still welcome in the Chinese market. The Chamber’s recent survey shows that preferential treatment of local companies has become the top regulatory business challenge in 2021, with one third of German companies experiencing unfavorable treatment. This tendency is rather detrimental to the commitment of companies to use their full potential to contribute to China’s decarbonization goals.

To better develop the potential of German companies and to encourage them to further develop the technologies outlined above, companies need to be clear about their role in the Chinese market. Be it bigger or smaller companies, they would like to be a part of China’s sustainable future and they need to be ensured that they play a role in the Chinese market and that chances are fair. Progress in this regard would be especially valuable since German companies are usually planning to be here for the long term.

Full content of Advocacy Paper can be download: https://china.ahk.de/advocacy

Like 16