Company Name: Brose China Co., Ltd.

Project Name: High performance sustainable electric climate compressor

Award Category: Innovation Sustainable Product

Product / Service Introduction

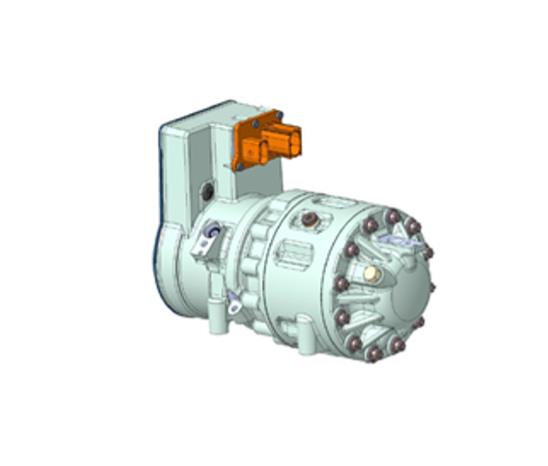

With the rapid popularization of new energy vehicles, the market demand for electric climate compressors is boomed. Meanwhile, at the background of "dual carbon“ strategy, the development of low-carbon thermal management technology and the improvement of thermal management efficiency have become a key trend. In August 2022, Brose presented a new high-voltage compressor concept--900V/8cc electric climate compressor, which uses CO2 as refrigerant and features higher sustainable performance.

Compared with mainstream large-displacement and high-voltage compressors, Brose's CO2 compressors have the characteristics of smaller size, higher speed, quieter and more outstanding low-temperature heat pump performance, which can effectively meet the various thermal management requirement of new energy vehicles.

Explanation of Circular Economy Practice

Currently, there are mainly three type of refrigerants for compressor: R134a, R1234yf and R744 (CO2). The GWP (Global Warming Index) of the three refrigerants is 1400, 4 and 1, respectively. R134a has been banned in Europe and the United States; although R1234yf is more environmentally friendly than R134a, it is more expensive; R744 (CO2 as a refrigerant) is much better for the needs of carbon reduction and environmental protection.

Moreover, we have increased the voltage application range of CO2 compressor from the existing 800V to 900V platform (up to 960V), to provide greater cooling power in a short time, which can effectively improve the problem of rapid heating of power battery under supercharging and fast-charging mode, ensuring the safety of the charging process.

In addition, we choose SiC MOSFET as the core component ECU. Compared with the traditional Si-based MOSFET and IGBT, the material characteristics can be directly transformed into system advantages, including smaller size, lower weight, smaller switching loss, which can further improve the overall performance of the compressor.

Overview of Product/Service Lifecycle

Product Design:

CO2 as a natural refrigerant is very friendly to the envrionment.

The overall design target is miniaturization, lightweight and compact.

No forbidden substance such as heavy metal Pb in ECU design and manufacturing process.

Production:

Manufacturing process is environmentally friendly,low-energy production equipment is used.

Significant use of renewable energy in manufacturing processes.

Useage:

CO2 refrigerant’s GWP index is 1, having lowest influence to global warming compared with other chemical refrigerants.

Better performance and efficiency in low-temperature heat pump condition, which is much more energy saving.

900V platform better supports vehicles’ fast charging.

Recycling and Recovery:

Choose high-silicon aluminum alloy as compressor housing material, which can be recycled for many times.

Components meet recycling requirement in China and other Europe and US market.